Italy has become a global leader in precision manufacturing, offering cutting-edge technology, skilled craftsmanship, and a wide range of services. Whether you're in the aerospace, automotive, or medical industry, CNC machining services in Italy can deliver the exact parts you need with unmatched precision.

CNC machining services in Italy are a game-changer for your business, how they work, and how to choose the right service provider for your next project. Keep reading to discover the key advantages of choosing Italian manufacturers and what makes them stand out globally..

What is CNC Machining and Why It Matters

CNC (Computer Numerical Control) machining is a manufacturing process where pre-programmed computer software controls the movement of machinery and tools. This process allows manufacturers to produce parts with extreme precision, making it ideal for industries requiring complex components.

From cutting metals and plastics to engraving and drilling, CNC machines handle tasks that would be impossible to complete manually with the same speed and accuracy. It's no surprise that CNC machining is a cornerstone of Italy's advanced manufacturing sector.

Types of Machining Services in Italy

Italy isn't just famous for its pasta and art; it's also a powerhouse in precision machining. If you're seeking top-notch manufacturing prowess, you're in the right place. Let's explore the various machining services that Italy brings to the table.

Turning

Ever wondered how raw metal becomes a finely crafted component? Turning is your answer. Using a lathe, material spins at high speeds while cutting tools shape it into desired forms. In Italy, turning isn't merely a process—it's an art form. Italian machinists leverage centuries of craftsmanship, combining traditional techniques with cutting-edge technology.

By harnessing CNC (Computer Numerical Control) turning machines, Italian workshops produce components with unmatched precision. Whether it's for automotive parts or intricate aerospace components, turning services in Italy ensure tight tolerances and impeccable finishes. The integration of advanced software allows for rapid prototyping and mass production alike, meeting diverse industry demands.

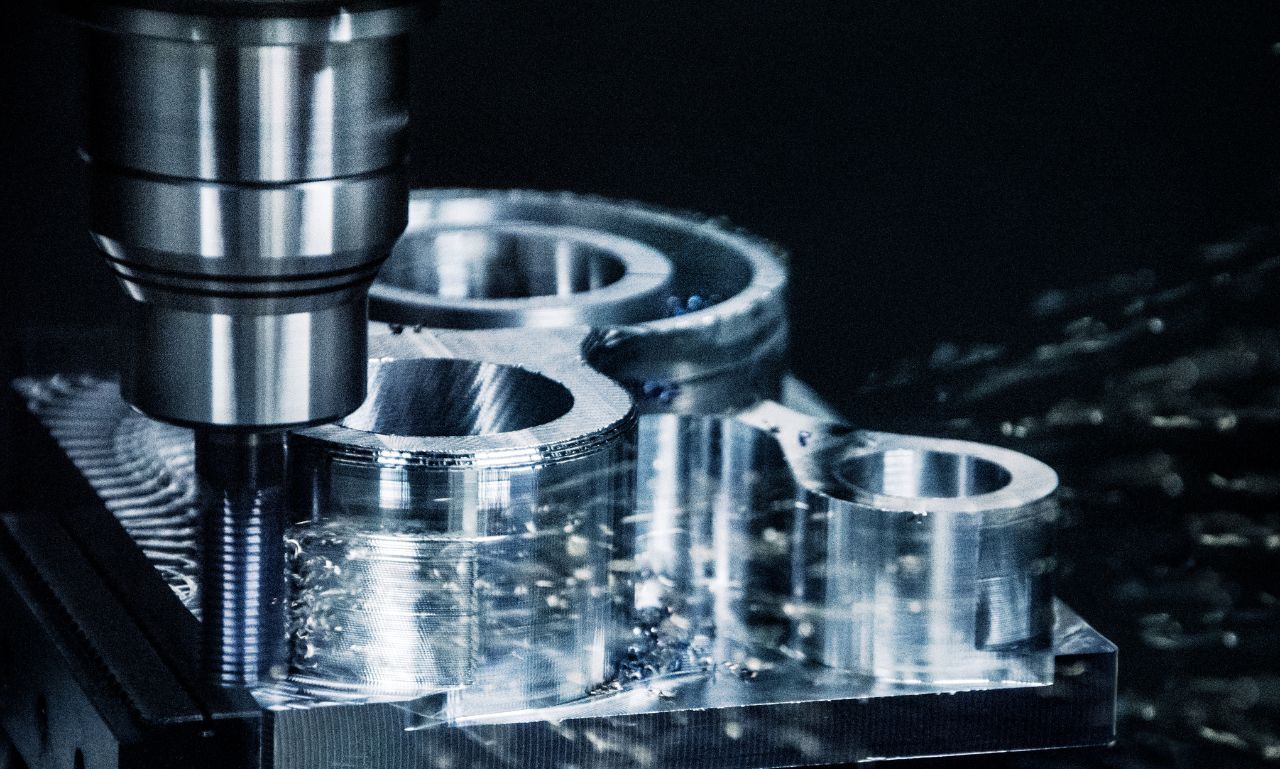

Milling

If turning shapes materials around an axis, milling carves out features across surfaces. Milling machines use rotating cutting tools to remove material, crafting complex geometries and surfaces. In Italy, milling services are elevated by a commitment to innovation and quality.

Italian milling services excel in both vertical and horizontal milling, accommodating a wide range of materials—from metals like aluminum and steel to composites and advanced plastics. With 5-axis milling machines, Italian workshops can produce components with intricate details, minimizing the need for multiple setups and reducing production times.

Need custom gears, engine components, or molds? Italy's milling services have got you covered. The combination of skilled artisans and state-of-the-art machinery ensures that every piece meets stringent quality standards. Plus, with CAD/CAM integration, designs move seamlessly from concept to reality.

Drilling

Drilling might sound straightforward, but in high-precision industries, it's anything but simple. Creating holes with exact dimensions and finishes is crucial. Italy's machining services bring precision drilling to new heights.

Whether you require deep-hole drilling, micro-drilling, or multi-axis drilling, Italian machining shops have the expertise. Utilizing advanced drill presses and CNC drilling machines, they can handle complex drilling tasks across various materials. The result? Components that fit perfectly every time.

Italy's drilling services ensure reliability and consistency for industries like aerospace and medical devices, where precision is non-negotiable. The use of specialized drills and cutting fluids minimizes tool wear and enhances surface finish, delivering superior results with every project.

Grinding

When surface finish and dimensional accuracy are paramount, grinding steps in. Grinding removes minimal material to achieve smooth surfaces and precise dimensions. Italy's grinding services are renowned for their meticulous attention to detail.

Italian machinists utilize various grinding techniques—surface grinding, cylindrical grinding, and centerless grinding—to meet diverse requirements. Whether it's preparing components for assembly or enhancing wear resistance, grinding ensures components meet exact specifications.

In sectors like automotive and hydraulics, where every micron counts, Italian grinding services deliver unmatched quality. With advanced machinery and experienced technicians, they can achieve tolerances within a few micrometers, ensuring optimal performance of the final product.

Electrical Discharge Machining (EDM)

Need to machine hard materials or complex shapes that traditional methods can't handle? EDM is your go-to solution. EDM uses electrical discharges to erode material, allowing for precision machining of conductive materials.

Italy’s machining services are at the forefront of EDM technology. Whether it's wire EDM or die-sinking EDM, Italian workshops can create intricate components with high precision. This process is ideal for producing tooling molds, intricate cavities, and components made from tough alloys.

One of the standout features of Italian EDM services is their ability to maintain tight tolerances and fine surface finishes. By leveraging advanced EDM equipment and control systems, they can produce components that meet the most demanding specifications.

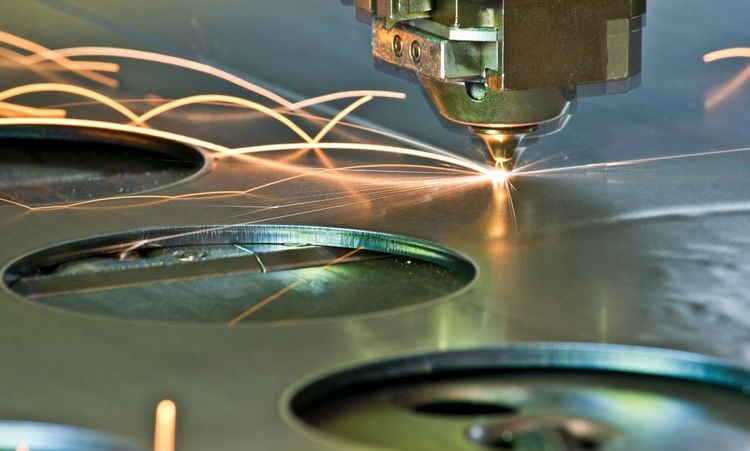

Laser Beam Machining

When precision meets non-contact machining, you get laser beam machining. This technique uses focused laser beams to remove material, allowing for high-precision cuts and engravings without mechanical force.

Italy’s machining landscape includes cutting-edge laser machining services. From cutting thin metal sheets to intricate engravings on complex surfaces, laser machining offers versatility. Italian services utilize both CO2 and fiber lasers to cater to different materials and applications.

Laser machining is particularly valuable in electronics, medical devices, and aerospace industries where precision and minimal thermal distortion are critical. Italian machinists ensure that laser processes are optimized for speed and accuracy, delivering components that meet stringent industry standards.

Common Applications of Machining in Italy

Italy’s machining services are not just about the processes—they’re about the industries they empower. Let's delve into how these services propel key sectors forward.

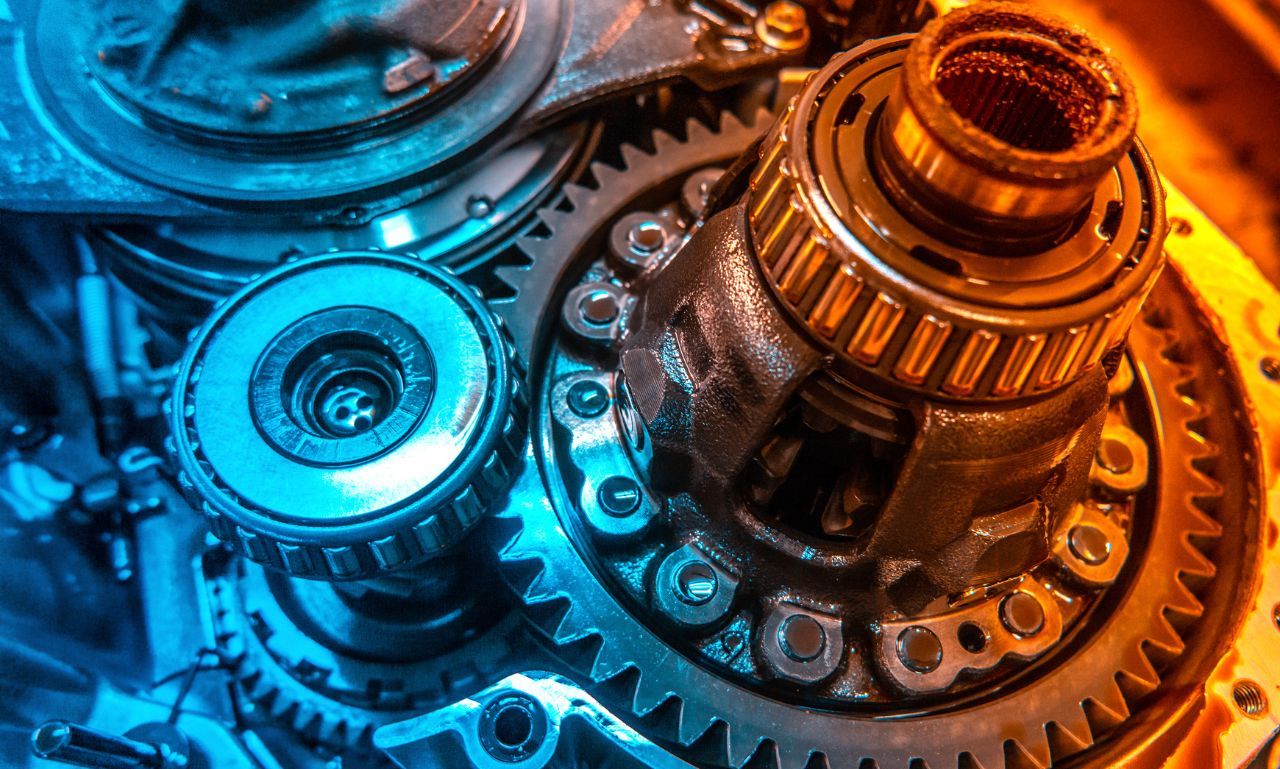

Automotive Industry

Italy and cars go together like a fine wine and cheese. From luxury brands like Ferrari and Lamborghini to mainstream manufacturers, the automotive industry relies heavily on precision machining.

Machining services in Italy produce engine components, transmission parts, braking systems, and more. With a focus on performance and safety, Italian machinists ensure each component meets exacting standards. The use of advanced materials and machining techniques enhances durability and efficiency.

Moreover, the rise of electric vehicles brings new machining challenges and opportunities. Italian machining services are adapting by crafting components for electric drivetrains and battery systems, pushing the envelope of innovation.

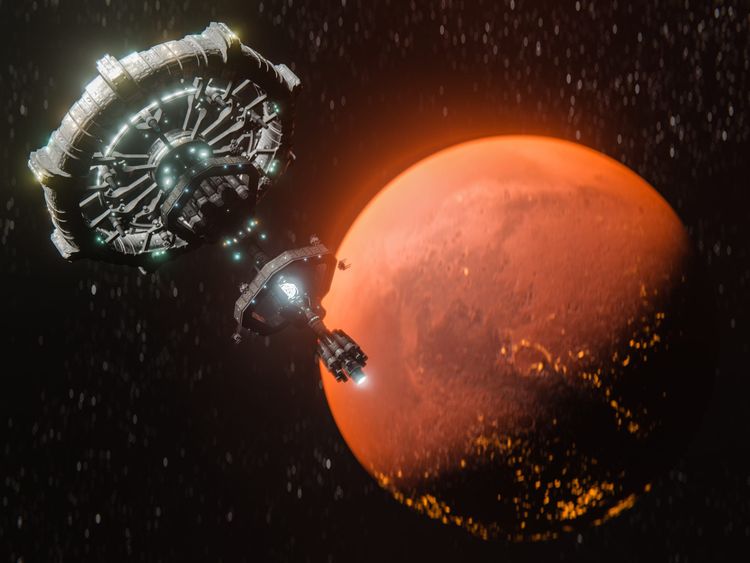

Aerospace Industry

When your components are hurtling through the sky at Mach speeds, precision is non-negotiable. The aerospace industry depends on machining services to produce parts that can withstand extreme conditions.

Italy's aerospace sector benefits from machining services that create turbine blades, structural components, and avionics housings. Using advanced alloys and composites, Italian machinists deliver parts that are both lightweight and robust.

The integration of advanced machining techniques, like 5-axis milling and EDM, allows for the production of complex geometries essential in aerospace applications. Italian services also adhere to strict quality assurance protocols, ensuring compliance with international aerospace standards.

Medical Equipment Manufacturing

In the medical field, lives hinge on the reliability of equipment and devices. Machining services play a crucial role in producing surgical instruments, prosthetics, and diagnostic equipment components.

Italian machining services specialize in medical-grade materials like titanium, stainless steel, and biocompatible plastics. Precision is key, and Italian workshops deliver with meticulous attention to detail.

Whether it’s crafting tiny components for implantable devices or large parts for imaging equipment, Italy's machining services combine technical expertise with a deep understanding of medical requirements. This synergy ensures that the final products are safe, effective, and of the highest quality.

Electronics

The electronics industry demands miniature components with intricate designs. Machining services in Italy rise to the challenge, producing parts for consumer electronics, industrial controls, and more.

Using techniques like micro-milling and laser machining, Italian services create components with tight tolerances and fine surface finishes. Materials like copper alloys, aluminum, and specialized plastics are commonly used.

In an era where devices are shrinking but capabilities are expanding, Italian machining services provide the precision manufacturing needed to keep pace with technological advancements. Their ability to produce small, complex parts enables innovation across the electronics sector.

Why Choose CNC Machining Services in Italy?

Italian precision machining services bring a unique set of advantages to the table:

1. World-Class Precision and Craftsmanship

Italy has a long history of precision engineering and manufacturing, and this legacy extends into modern CNC machining services. Italian manufacturers are renowned for producing parts with tight tolerances, perfect finishes, and precise measurements, ensuring every product meets exact specifications.

2. Cutting-Edge Technology

Italian CNC machining companies are known for using the latest technology in manufacturing processes. From 5-axis CNC machines to automated systems, these businesses invest heavily in state-of-the-art equipment to ensure high productivity and unmatched quality.

By leveraging advanced technology, CNC machining services in Italy can handle complex designs, tight deadlines, and large-scale production runs without sacrificing quality.

3. Wide Range of Materials

Whether you need parts made from metals like aluminum, steel, or titanium, or from specialized materials like plastics, ceramics, or composites, Italian CNC machining services can cater to your needs. These manufacturers are equipped to handle a wide variety of materials, providing flexibility for a wide range of industries.

4. Customization and Versatility

Italian CNC manufacturers excel in producing customized parts tailored to specific industry needs. Whether you need a one-off prototype or a large production run, CNC services in Italy can adapt to your project's requirements with high precision and consistency.

5. Industry Expertise

Italy is a hub for numerous industries, including aerospace, automotive, defense, medical, and luxury goods. Italian CNC machining services have experience working with global clients and high-profile industries, offering a wealth of expertise in delivering components for critical applications.

Their experience with high-standard industries translates to superior quality control, ensuring that every part they manufacture meets the strictest international standards.

By leveraging these advantages, you can streamline your production, enhance product quality, and gain a competitive edge in your market.

Materials Used in Machining in Italy

Materials are the backbone of any machining process. Italy's machining services handle a diverse array of materials, each chosen for specific properties and applications.

Metals

From the classic to the advanced, metals remain a staple in machining. Italian services work with a variety of metals, including:

- Steel: Ideal for strength and durability, used in automotive and structural applications.

- Aluminum: Lightweight and corrosion-resistant, perfect for aerospace and electronics.

- Titanium: High strength-to-weight ratio, used in aerospace and medical devices.

- Copper and Brass: Excellent electrical conductivity for electronics and plumbing components.

Italian machinists understand the nuances of each metal, selecting appropriate cutting tools, speeds, and feeds to achieve optimal results.

Plastics

Don’t underestimate the role of plastics in modern machining. Italian services machine a variety of plastics, including:

- Polycarbonate: Impact-resistant, used in protective equipment.

- ABS: Common in consumer electronics and automotive interiors.

- PTFE (Teflon): Chemical-resistant, ideal for medical and chemical industry components.

- POM (Delrin): High stiffness and low friction, used in mechanical components.

Machining plastics requires specialized techniques to prevent issues like melting or deformation. Italian workshops employ strategies like sharp tooling and controlled feeds to ensure high-quality plastic components.

Composites

As industries seek materials with specific properties, composites have gained prominence. Italian machining services handle composites like:

- Carbon Fiber Reinforced Polymers (CFRP): High strength and low weight for aerospace and automotive parts.

- Glass Fiber Composites: Used in marine and sporting equipment.

- Ceramic Composites: High-temperature resistance for industrial applications.

Machining composites presents challenges due to their abrasive nature and layered structures. Italian machinists utilize specialized tools and techniques to achieve clean cuts and precise dimensions.

Specialized Materials

For niche applications, specialized materials come into play. Italian machining services are adept at working with:

- Superalloys (Inconel, Hastelloy): High-temperature resistance for turbine components.

- Magnesium Alloys: Ultra-lightweight for aerospace and automotive applications.

- Biomedical Materials (NiTi alloys): Used in medical implants and devices.

These materials often require unique machining approaches. Italian services invest in advanced tooling and process development to effectively machine these challenging materials.

Why Consider Italian CNC Machining Services for Complex Parts?

When your project demands intricate geometries and tight tolerances, Italian CNC machining services are the answer. Their mastery of computer-aided manufacturing allows them to produce highly complex parts with exceptional accuracy and repeatability. From aerospace components to medical implants, Italian CNC machining delivers the precision you need.

Selecting Machining Services in Italy

Choosing the right machining partner is crucial to your project's success. Here are key factors to consider when selecting machining services in Italy.

Provider Expertise

You want a provider who knows the ins and outs of machining. Italian services often possess deep expertise across various industries. Look for:

- Industry Experience: Has the provider worked in your industry before?

- Technical Knowledge: Do they understand the specific requirements of your project?

- Skilled Workforce: Are their machinists trained and experienced?

Italian machining shops pride themselves on their skilled artisans and engineers. Their expertise ensures your components are manufactured to the highest standards.

Range of Services Offered

A one-stop-shop can simplify your supply chain. Assess whether the provider offers:

- Multiple Machining Processes: Turning, milling, grinding, EDM, etc.

- Material Capabilities: Can they work with the materials you require?

- Additional Services: Heat treatment, surface finishing, assembly.

Italian machining services often provide comprehensive solutions, reducing the need to coordinate between multiple vendors.

Quality Assurance Practices

Quality isn't just a buzzword—it's critical to your success. Evaluate the provider's quality assurance protocols:

- Certifications: ISO 9001, AS9100 (aerospace), ISO 13485 (medical devices), etc.

- Inspection Capabilities: Do they have advanced inspection equipment like CMMs (Coordinate Measuring Machines)?

- Process Controls: How do they ensure consistency and traceability?

Italy's machining services typically adhere to stringent quality standards, offering peace of mind that your components will meet or exceed your specifications.

Meeting Project Needs and Deadlines

Time is money, and delays can be costly. Consider the provider's ability to:

- Scale Production: Can they handle both small runs and large volumes?

- Lead Times: What are their typical turnaround times?

- Communication: Are they responsive and proactive in addressing your needs?

Italian providers are known for their reliability and commitment to customer satisfaction. Clear communication and efficient processes help keep your project on track.

Ready to leverage Italy's exceptional machining services for your next project? Don't settle for less—partner with the best and bring your vision to life.